Advanced machining of high-performance materials

Objective: Enhancing precision, efficiency, and surface integrity while minimizing tool wear and cutting force in advanced machining of high-performance materials.

Selected publications:

[1]. Wang, H., Hu, Y.B., Cong, W.L., Hu, Z.Y., & Wang, Y.Q. (2020). A novel investigation on horizontal and 3D elliptical ultrasonic vibrations in rotary ultrasonic surface machining of CFRP composites. Journal of Manufacturing Processes, 52, 12-25.

[2]. Wang, S., Zheng, C., Li, S., Guo, A., Qu, P., & Hu, Y.B. (2023). Free vibration of functionally graded carbon nanotube‐reinforced composite damping structure based on the higher‐order shear deformation theory. Polymer Composites, 44(2), 873-885.

[2]. Wang, H., Hu, Y.B., Ning, F.D., & Cong, W.L. (2020). Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: effects of ultrasonic frequency on microstructural and mechanical properties. Journal of Materials Processing Technology, 276, 116395.

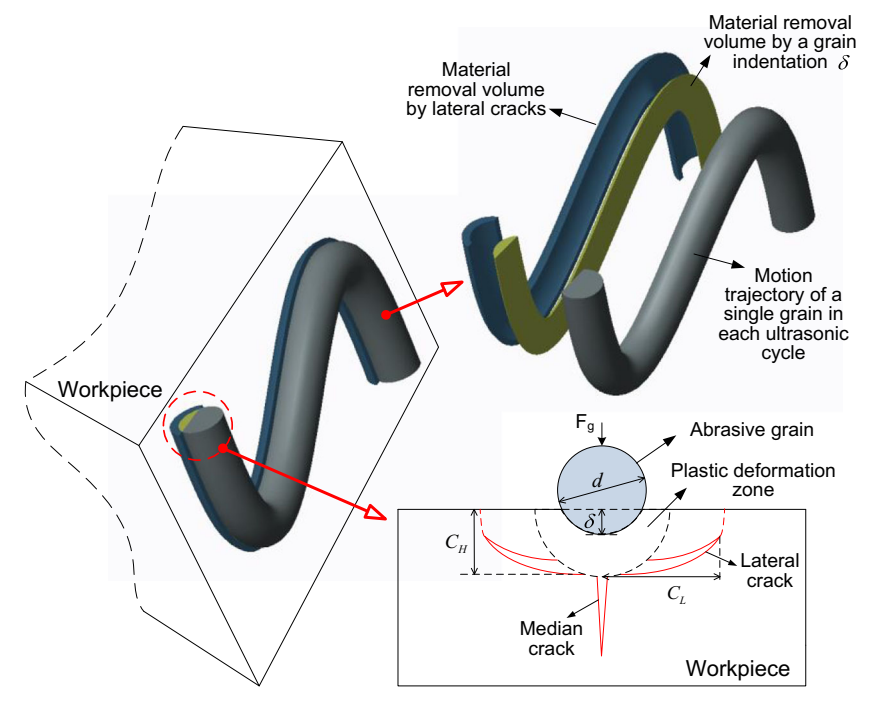

[3]. Wang, H., Hu, Y.B., Cong, W.L., & Hu, Z.L. (2019). A mechanistic model on feeding-directional cutting force in surface grinding of CFRP composites using rotary ultrasonic machining with horizontal ultrasonic vibration. International Journal of Mechanical Sciences, 155, 450-460.

[4]. Wang, H., Ning, F.D., Li, Y.C., Hu, Y.B., & Cong, W.L. (2019). Scratching-induced surface characteristics and material removal mechanisms in rotary ultrasonic surface machining of CFRP. Ultrasonics, 97, 19-28.