Additive Innovation in Manufacturing

(AIM) Laboratory

@ Mississippi State University

News

- Mr. Guo made a presentation titled "Quality Improvement in Vat Photopolymerization of Ceramic Hollow Structures: Effects of Nanofill Thermal Buffering Method" at the IMECE 2025. (Nov. 2025)

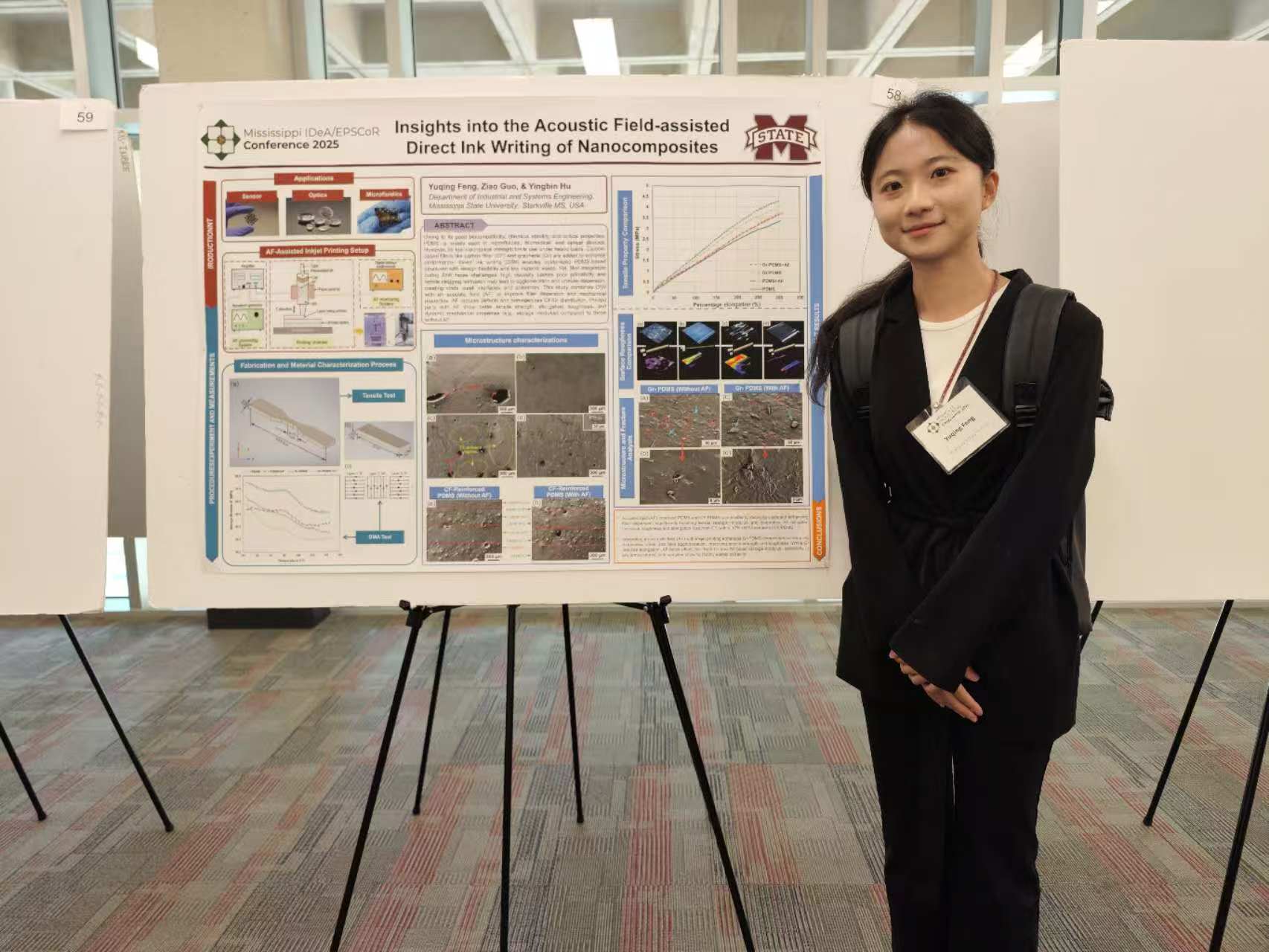

- Ms. Yuqing Feng made her first presentation titled "Process Optimization in Additive Manufacturing of Hollow-Structured Nanocomposites via Machine Learning" at the IMECE 2025. (Nov. 2025)

- Dr. Hu chaired the "Artificial Intelligence Applications in Manufacturing I" session at IMECE 2025 held in Memphis, TN. (Nov. 2025)

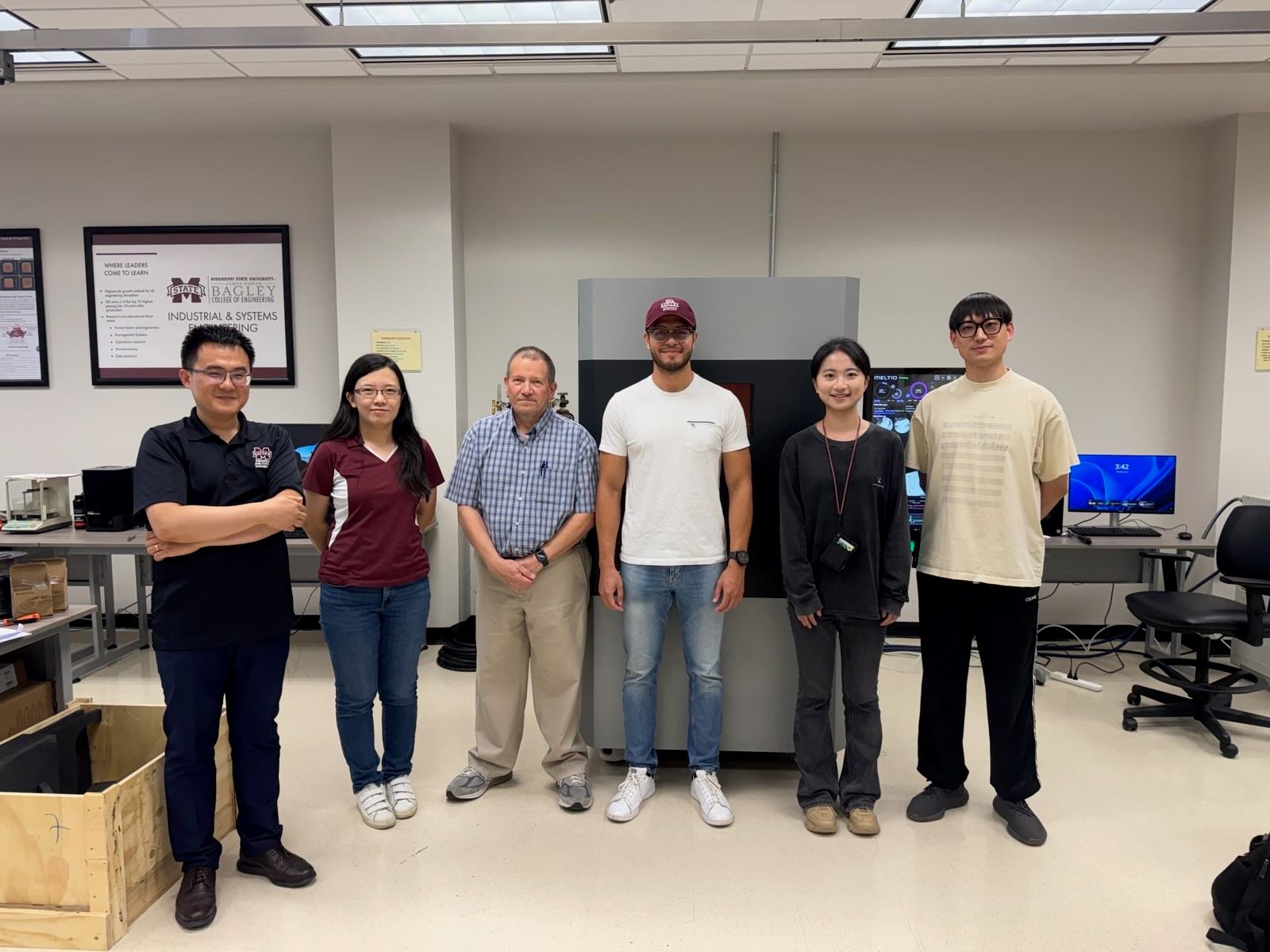

- In collaboration with AimUp & Dr. Smith, Dr. Hu hosted a two-day, hands-on additive manufacturing workshop. (Nov. 2025)

- Dr. Hu (sole PI) received the Mississippi Research Alliance seed grant. (Oct. 2025)

- Three manuscripts were accepted to publish in IMECE conference & expo. (2025)

- Dr. Hu serves as a Co-PI on a project sponsored by DoD. (Sep., 2025)

- Mr. Owen Smith joined our team as a Master student, welcome! (Aug. 2025)

- Dr. Hu serves as a Co-PI on a project sponsored by DoD (Jun., 2025)

- Mr. Blake Ray joined our team as a Ph.D. student, welcome! (Jun. 2025)

- Mr. Ziao Guo made his first presentation titled 4D printing of polymer-derived ceramics with high-resolution and shape memory effects at the IISE conference held in Atlanta, GA (Jun. 2025)

- Ziao joined our research team, Welcome! (Jan. 2025)

- Yuqing joined our research team. Welcome! (Jan. 2025)

- Matthew joined our research team. Welcome! (Jan. 2025)

- Dr. Hu's research paper, which is titled "Additive manufacturing of bionic layered ceramic-metal composites for enhanced toughness and damage resistance" was published in Virtual and Physical Prototyping. (Dec. 2024)

- Dr. Hu has received the MU Junior Faculty Scholar Award. Congrats! (May 2024)

- Dr. Hu's research paper, which is titled "Vat photopolymerization of sponge bone needle bionic structure with high strength and toughness by mimicking golden spiral of nautilus" was published in Journal of Manufacturing Processes (Aug. 2024)

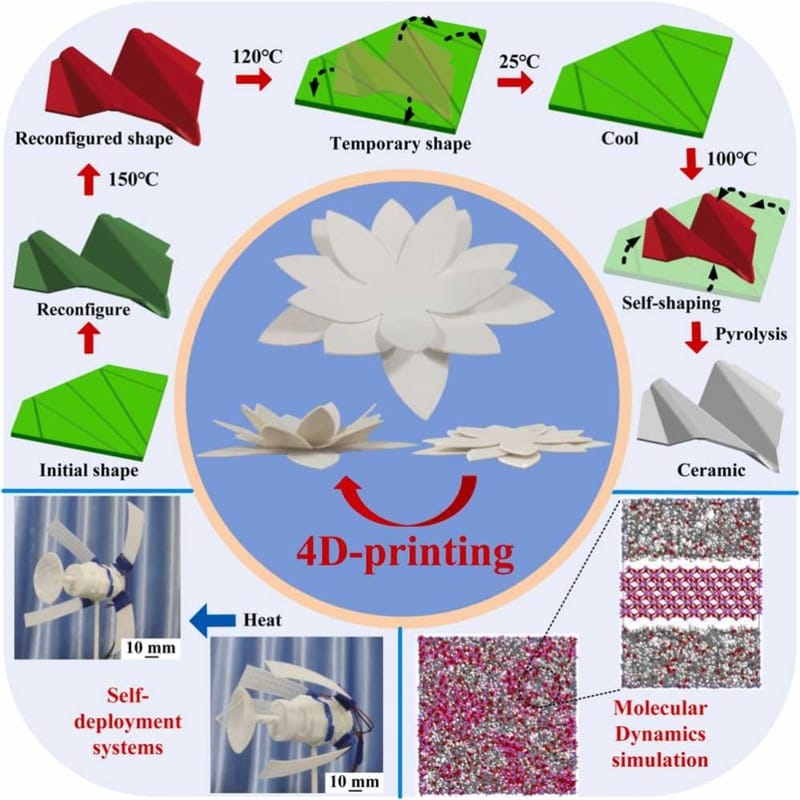

- Dr. Hu's research paper, which is titled "Four-dimensional printing of polymer-derived ceramics with high-resolution, reconfigurability, and shape memory effects" was published in Additive Manufacturing (March 2024)

- Dr. Hu has been selected as a member of the 2023-24 Advancing Teacher Scholars (ATS) Community. (April 2023)

- Partha received Graduate Students’ Achievement Award (GSSA). Congrats! (April 2023)

- Dr. Hu gave a presentation on “Acoustic Field-assisted Additive Manufacturing” to the United Performance Metals visit on in April, 2023.

- Dr. Hu participated the Make it Miami event on Apr. 7, 2023 and held the MME academic session.

- Dr. Hu’s research paper, which is entitled “Method for preparing damage-resistant 3D-printed ceramics via interior-to-exterior strengthening and toughening“, was published in Additive Manufacturing. (Dec. 2022)

- Dr. Hu serves as an associate editor of the Materials Journal. (2022 – present)

- Dr. Hu served as a session co-chair of the ASME 2022 International Manufacturing Science and Engineering Conference in June 2022.

- Dr. Hu attended the conference of Advanced Manufacturing: Research & Education in April 2022

- Dr. Hu has been honored with Vebleo Fellow Jr. in 2022.

- Dr. Hu serves as a committee member in the Vebleo webinar.

- Dr. Hu received competitive Tech Fee grant of $44,855 from Miami University.

- I cordially invite you to contribute a research paper or review to my Special Issue, entitled Advances in Field-Assisted Additive Manufacturing, for the open access journal Materials (ISSN 1996-1944, IF: 3.057).

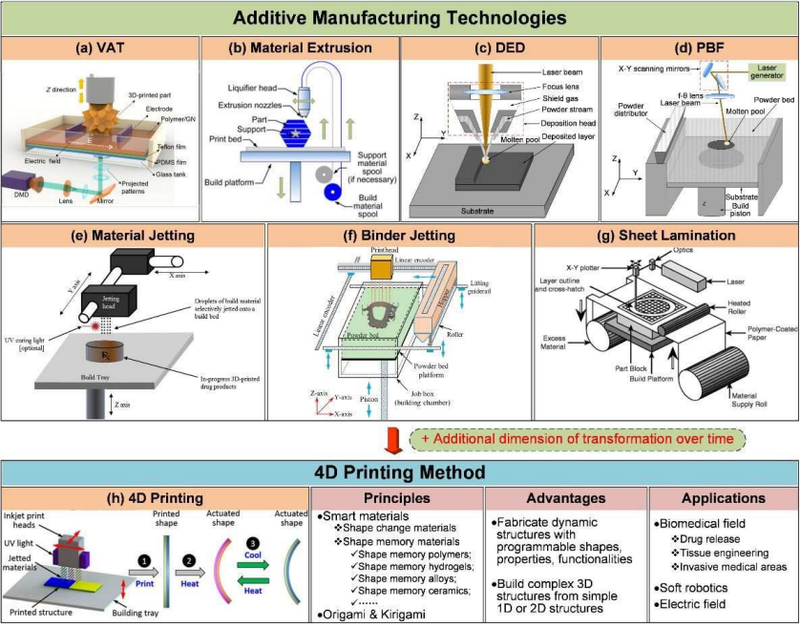

- The LAX team (Senior Capstone Project) won the Humanitarian Award, congratulations!

- Chang Liu received the MU USS award, congratulations!

- Dr. Hu received the 2020-2021 MU Committee on Faculty Research Award!

- Partha P. Pandit Joined our research team. Welcome!

- Dr. Hu’s review paper, which is entitled “Recent Progress in Field-Assisted Additive Manufacturing: Materials, Methodologies, and Applications“, was published in Materials Horizons.

- Zhicheng Rong & Chang Liu received Undergraduate Research Award, which was highlighted on Miami University CEC news. Congrats!

- Dr. Yingbin Hu is granted patent on tailoring nano/micro-scaled porous structures using selective laser alloying, which is highlighted on Miami University CEC news.

People

Owen Smith

Master Student

Department of Industrial & Systems Engineering

Research & Grants

Teaching

Mississippi State University

- IE 3323: Manufacturing Processes (Spring & Fall 2025; Fall 2024)

- IE 8333: Production Control System (Fall 2024)

Miami University

- MME 231: Manufacturing Processes (Spring & Fall in 2020, 2021; & 2022; Fall 2023; Spring 2024)

- MME 470B/570B: Fracture Mechanics (Fall 2021; Fall 2022)

- MME 312: Mechanics of Materials (Winter 22-23, 23-24; Summer 23-24)

- MME 223: Engineering Materials (Fall 2019)

- MME 610: Graduate Seminar (Spring 2022 & 2024)

Texas Tech University

- IE 4331: 3D Printing and Additive Manufacturing (Spring 2019)

Services

Committee

- MSU Graduate Committee (2024-present)

- MU Senate member (2023 – 2024)

- MU MiamiTHRIVE Develop Ecosystems of Excellence in Research & Scholarship committee (2024)

- Member of the Humanitarian Engineering and Computing Minor (HE&C) committee (2023 – 2024)

- Member of the research engineer searching committee (2022 – 2023)

- Member of the MME petition committee (fall 2022 & fall 2023)

- Member of the MME Ad Hoc Design Committee (2020 – 2024)

- Chair / member of thesis committee over ten graduate students

- Member of the 2023-24 Advancing Teacher Scholars Community

Professional

- Guest Editor of the Journal of Manufacturing and Materials Processing journal

- Panel member for DoD National Defense Science and Engineering Graduate

- Vebleo fellow Jr. & Serving as a committee member of the Vebleo webinar

- Special issue editor (guest editor) of the “Advances in Field-Assisted Additive Manufacturing”

- Session chair in 2025 IMECE International Mechanical Engineering Congress.

- Session chair in 2025 IISE Annual Conference & Expo.

- Session co-chair in SME 2023 North American Manufacturing Research Conference (NAMRC 51)

- Session co-chair in ASME 2022 & 2019 International Manufacturing Science and Engineering Conference (MSEC)

- Member of the Institute of Industrial and Systems Engineers (IISE) (2024 - present)

- Member of the Society of Manufacturing Engineers (SME) (2023 – present)

- Member of the American Society of Mechanical Engineers (ASME) (2017 – present)

- Peer reviewer of journals and conferences:

- Advanced Composites and Hybrid Materials

- Advanced Functional Materials

- Additive Manufacturing

- Biotechnology and Bioengineering

- Ceramics International

- Composites Part A

- Composites Part B: Engineering

- Composite Structures

- Defense Technology

- Engineering Science and Technology, an International Journal

- International Journal of Materials and Product Technology

- International Journal of Mechanical Science

- Journal of Biomedical Materials Research Part B-Applied Biomaterials

- Journal of Composites Science

- Journal of Magnetism and Magnetic Materials

- Journal of Manufacturing Processes

- Journal of Materials Processing Technology

- Lasers in Engineering

- Machines

- Materials

- Materials Chemistry and Physics

- Materials Characterization

- Materials Letters

- Nature Communications

- Optics & Laser Technology

- Pharmaceutics

- Polymers

- Sustainability

- Virtual and Physical Prototyping

- 3D Printing and Additive Manufacturing

- SME NAMRC

- ASME-MSEC

- Judge of the 18th & 17thAnnual Graduate Student Research Poster Competition (2019, 2018)

- Mentored an engineering college-supported international graduate, and three REU students (2016 – 2019)

Publications

Refereed Journal Articles

[J59]. Rugerinyange, A., Hu, Y.B., Jahan, M. (2025). Enhancing compressive properties of SLS-printed Nylon lattice structures using continuous-rotation thermoset coatings and graphene nanofillers. The International Journal of Advanced Manufacturing Technology, https://doi.org/10.1007/s00170-025-16644-y

[J58]. Wu, H.L., Guo, A.F., Kong, D.K., Sheng, X.L., Liu, C., Wu, J.W., Qu, P., Wang, S.Q., Guo, S., Hu, Y.B., Chen, Z.W. (2025). Additive manufacturing of bionic layered ceramic-metal composites for enhanced toughness and damage resistance. Virtual and Physical Prototyping, 20(1), e2443102.

[J57]. Kong, D.K., Guo, A.F., Wu, H.L., Li, X.J., Wu, J.W., Wang, H.B., Hu, Y.B*., Qu, P., & Wang, S.Q. (2024). Vat photopolymerization of sponge bone needle bionic structure with high strength and toughness by mimicking the golden spiral of nautilus. Journal of Manufacturing Processes, 124, 1-11.

[J56]. Guo, A., Li, S., Wang, S., Zhai, Z., Qu, P., Guo, S., Kong, H., Tang, R., Liu, C., Han, W. & Hu, Y.B. (2024). “Digital light processing of multi-walled carbon nanotubes-reinforced photosensitive resin composites: effects on microstructures and mechanical properties.” Journal of Materials Research and Technology, 28, 434-445.

[J55]. Liu, C., Wu, H.L., Guo, A.F., Kong, D.K., Zhao, Z.Y., Wang, L., Yin, L.F., Xia, G.J., Su, X.F., & Hu, Y.B*. (2024). Vat photopolymerization of sepiolite fiber and 316L stainless steel-reinforced alumina with functionally graded structures. Materials, 17(12), 2973.

[J54]. Wu, H.L Guo, A.F., Kong, D.K., Li, X.J., Wu, J.W., Wang, H.B., Qu, P., Wang, S.Q., Guo, S., Liu, C., Zhao, Z.Y., Gallaspie, J.G., Hu, Y.B. (2024). Vat photopolymerization of nacre-like carbon fiber reinforced biomimetic ceramic composites. Ceramics International, 50(14), 25388-25399.

[J53]. Kong, D.K., Guo, A.F., Wu, H.L., Li, X.J., Wu, J.W., Hu, Y.B.*, Q, P., & Wang, S.Q. (2024). Four-dimensional printing of polymer-derived ceramics with high-resolution, reconfigurability, and shape memory effects. Additive Manufacturing, 83, 104050.

[J52]. Kong, D.K., Guo, A.F., Hu, Y.B.*, Zhou, X.Y., Wu, H.L., Li, X.J., Q, P., & Wang, S.Q. (2023). Alumina-based ceramic cores prepared by vat photopolymerization and buried combustion method. Materials Today Communications, 37, 107434.

[J51]. Wang, H.L., Guo, A.F.*, Kong, D.K., Li, X.J., Wu, J.W., Hu, Y.B.*, Qu, P., Wang, S.Q., Wu, Y. & Liu, C. (2023). Vat photopolymerization of sepiolite fiber-toughened alumina: microstructure and rheological, physical, and mechanical properties. Materials Today Communications, 37, 107329.

[J50]. Guo, A.F., Tang, R.J., Guo, S., Hu, Y.B*., Sheng, X.L., Zhang, Y.B., Zhang, M.K., Qu, P., & Wang, S.Q. (2023). Acoustic field-assisted powder bed fusion of tungsten carbide-reinforced 316l stainless steel composites. Journal of Materials Processes and Technology, 26, 5488-5502. (IF:6.4)

[J49]. Li, Y.Z., Zhang, D.Z., Hu, Y.B., & Cong, W.L. (2023). Laser directed energy deposition of CoCrFeNiTi high entropy alloy coatings: effects of powder geometry and laser power. International Journal of Advanced Manufacturing Technology, 126, 3023-3038. (IF: 3.4)

[J48]. Wu, Y., Tang, R.J., Guo, A.F., Tao, X.D., Hu, Y.B*., Sheng, X.L., Qu, P., Wang, S.Q., Li, J.F., & Li, F.Y. (2023). Enhancing starch-based packaging materials: optimization of plasticizers and process parameters. Materials, 16(17), 5953. (IF: 3.4)

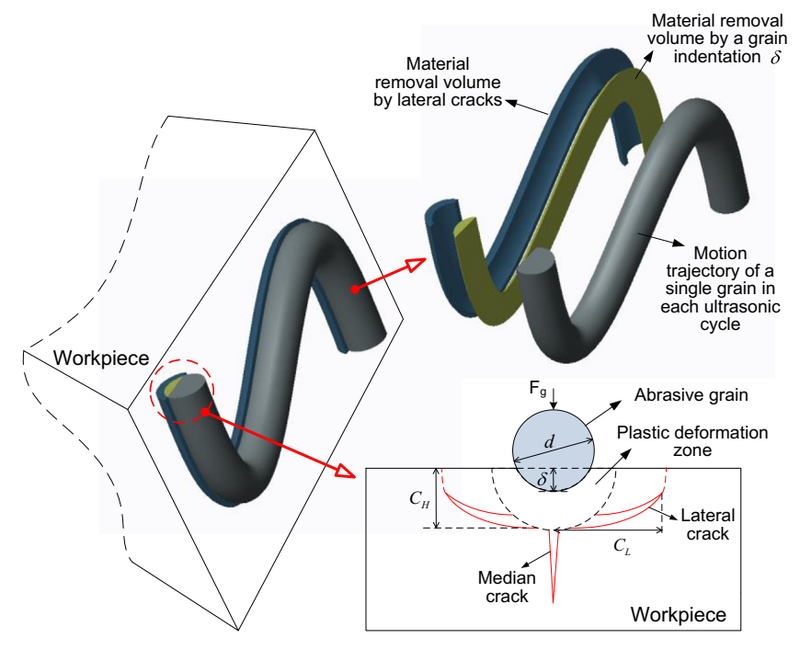

[J47]. Li, Y.Z., Garbie, M., Hu, Y.B., & Cong, W.L. (2023). The effects of scratching speed in ultrasonic vibration-assisted single diamond scratching process. Manufacturing Letters, 35, 289-296. (IF: 3.9)

[J46]. Liu, C., Pandit, P.P., Li, Y.Z., Cong, W.L., & Hu, Y.B*. (2023). Insights into the effects of an acoustic field-assisted on inkjet printing of graphene-reinforced polydimethylsiloxane composites. Manufacturing Letters, 35, 717-724.

[J45]. Guo, A.F., Zhou, X.Y., Kong, D.K., Kong, H., Wang, H.B., Zhu, Y., Qu, P., Wang, S.Q., & Hu, Y.B*. (2023). An insight into the effects of epoxy coating agent and sintering temperature on vat photopolymerization-printed Al2O3 parts. Ceramics International, 49(11), 19227-19240. (IF: 5.2)

[J44]. Guo, A.F., Wang, J. Tang, R.J., Kong, H., Kong, D.K., Qu, P., Wang, S.Q., Wang, H.B., & Hu, Y.B*. (2023). Insights into the effects of epoxy resin infiltration on powder aging issue induced by powder recycling in powder bed fusion of Nylon 12 materials. Journal of Materials Research and Technology, 23, 3151-3165. (IF:6.4)

[J43]. Guo, A.F., Tao, X.D., Kong, H., Zhou, X.Y., Wang, H.B., Li, J.F., Li, F.Y., & Hu, Y.B*. (2023). Effects of aluminum hydroxide on mechanical, water resistance, and thermal properties of starch-based fiber-reinforced composites with foam structures. Journal of Materials Research & Technology. 23, 1570-1583. (IF:6.4)

[J42]. Li, Y.Z., Hu, Y.B., Zhang, D.Z., & Cong, W.L. (2023). Laser remelting of CoCrFeNiTi high entropy alloy coatings fabricated by directed energy deposition: effects of remelting laser power. Optics & Laser Technology, 158, 108871. (IF: 5.0)

[J41]. Pandit, P.P., Liu, C., Iacono, S., Corti, G., & Hu, Y.B*. (2022). Microstructural characterization and property of carbon fiber reinforced high-density polyethylene composites fabricated by fused deposition modeling. Materials, 16(1), 180. (IF: 3.4)

[J40]. Guo, A.F., Kong, D.K., Zhou, X.Y., Kong, H., Qu, P., Wang, S.Q., Wang, H.B., & Hu, Y.B*. (2022). Method for preparing damage-resistant 3D-printed ceramics via interior-to-exterior strengthening and toughening. Additive Manufacturing. 60, 103172. (IF: 11.0)

[J39]. Wang, S.Q., Zheng, C.S., Li, S., Guo, A.F., Qu, P., & Hu, Y.B*. (2022). Free vibration of functionally graded carbon nanotube-reinforced composite damping structure based on the higher-order shear deformation theory. Polymer Composites. 44(2), 873-885. (IF: 5.2)

[J38]. Guo, A.F., Liu, C.C., Li, S., Zhou, X.Y., Wang, J., Wang, S.Q., Qu, P., & Hu, Y.B*. (2022). Water absorption rates and mechanical properties of fused deposition molding-printed continuous carbon fiber-reinforced nylon composites. Journal of Materials Research and Technology. 21, 3098-3112. (IF: 6.4)

[J37]. Guo, A.F., Kong, D.K., Zhou, X.Y., Qu, P., Wang, S.Q., & Hu, Y.B*. (2022). Evaluation of material reuse degree in additive manufacturing by the improved resolution coefficient grey correlation method. Process Safety and Environmental Protection, 166, 451-460. (IF: 7.8)

[J36]. Wang, S.Q., Guo, A.F., Liang, S., Qu, P., Hu, Y.B*., & Liu, C.C. Structural dynamic properties of stiffened composite plates with embedded multi-layered viscoelastic damping membranes. Mechanics of Advanced Materials and Structures. 30(22), 4536-4549. (IF: 2.8)

[J35]. Liu, C., Pandit, P.P., Parsons, C., Khan, F., & Hu, Y.B*. (2022) Acoustic field-assisted inkjet-based additive manufacturing of carbon fiber-reinforced polydimethylsiloxane composites. Journal of Manufacturing Processes, 80, 87-94. (IF: 6.2)

[J34]. Hu, Y.B*. (2021). Recent progress in field-assisted additive manufacturing: materials, methodologies, and applications. Materials Horizons, 8, 885-911. (IF: 13.3)

[J33]. Hu, Y.B., Wang, H., Cong, W.L., & Zhao, B. (2020). Directed energy deposition of ZTA ceramic: novel microstructure formation and mechanical performance. Journal of Manufacturing Science and Engineering-Transactions of the ASME, 142(2), 021005. (IF: 4.0)

[J32]. Wang, H., Hu, Y.B., Cong, W.L., Hu, Z.Y., & Wang, Y.Q. (2020). A novel investigation on horizontal and 3D elliptical ultrasonic vibrations in rotary ultrasonic surface machining of CFRP composites. Journal of Manufacturing Processes, 52, 12-25. (IF: 6.2)

[J31]. Wang, H., Hu, Y.B., Ning, F.D., & Cong, W.L. (2020). Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: effects of ultrasonic frequency on microstructural and mechanical properties. Journal of Materials Processing Technology, 276, 116395. (IF: 6.3)

[J30]. Maharubin, S., Hu, Y.B., Sooriyaarachchi, D., Cong, W.L., & Tan, Z. (2019). Laser engineered net shaping of antimicrobial and biocompatible titanium-silver alloys. Materials Science & Engineering C, 105, 110059. (IF: 7.33)

[J29]. Wang, H., Hu, Y.B., Cong, W.L., & Hu, Z.L. (2019). A mechanistic model on feeding-directional cutting force in surface grinding of CFRP composites using rotary ultrasonic machining with horizontal ultrasonic vibration. International Journal of Mechanical Sciences, 155, 450-460. (IF: 7.3)

[J28]. Wang, H., Hu, Y.B., Cong, W.L., & Burks, A. (2019). Rotary ultrasonic machining of carbon fiber reinforced plastic composites: effects of ultrasonic frequency. The International Journal of Advanced Manufacturing Technology, 104, 3759-3772. (IF: 3.4)

[J27]. Wang, H., Ning, F.D., Li, Y.C., Hu, Y.B., & Cong, W.L. (2019). Scratching-induced surface characteristics and material removal mechanisms in rotary ultrasonic surface machining of CFRP. Ultrasonics, 97, 19-28. (IF: 4.2)

[J26]. Wang, H., Hu, Y.B., Cong, W.L., & Burks, A. (2019). Rotary ultrasonic surface machining of CFRP composites: effects of horizontal ultrasonic vibration. Procedia Manufacturing, 34, 399-407.

[J25]. Hu, Y.B., Cong W.L., Wang, X.L., Li, Y.C., Ning, F.D., & Wang, H. (2018). Laser deposition-additive manufacturing of TiB-Ti composites with novel three-dimensional quasi-continuous network microstructure: effects on strengthening and toughening. Composites Part B: Engineering, 133, 91-100. (IF: 13.1)

[J24]. Hu, Y.B., Ning, F.D., Cong, W.L., Li, Y.C., Wang, X.L., & Wang, H. (2018). Ultrasonic vibration-assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties. Ceramics International, 44(3), 2752-2760. (IF: 5.2)

[J23]. Hu, Y.B., Ning, F.D., Wang, H., Cong, W.L., & Zhao, B. (2018). Laser engineered net shaping of quasi-continuous network microstructural TiB reinforced titanium matrix bulk composites: microstructure and wear performance. Optics & Laser Technology, 99, 174-183. (IF: 5.0)

[J22]. Hu, Y.B., & Cong, W.L. (2018). A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceramics International, 44(17), 20599-20612. (IF: 5.2)

[J21]. Ning, F.D., Hu, Y.B., Liu, Z.C., Wang, X.L., Li, Y.Z., Cong, W.L. (2018). Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: microstructural and mechanical characterization. Journal of Manufacturing Science and Engineering-Transactions of the ASME, 140(6), 061012. (IF: 4.0)

[J20]. Ning, F.D., Hu, Y.B., & Cong, W.L. (2018). Microstructure and mechanical property of TiB reinforced Ti matrix composites fabricated by ultrasonic vibration-assisted laser engineered net shaping. Rapid Prototyping Journal, 25(3), 581-591. (IF: 3.9)

[J19]. Li, Y.C., Ren, C.Z., Wang, H., Hu, Y.B., Ning, F.D., Wang, X.L., & Cong, W.L. (2019). Study of material removal mechanisms in grinding of C/SiC composites via single abrasive scratching testing. Ceramics International. 45(4), 4729-4738. (IF: 5.2)

[J18]. Li, Y.C., Ren, C.Z., Wang, H., Hu, Y.B., Ning, F.D., Wang, X.L., & Cong, W.L. (2019). Edge surface grinding of CFRP composites using rotary ultrasonic machining: comparison of two machining methods. The International Journal of Advanced Manufacturing Technology. 100(9-12), 3237-3248. (IF: 3.4)

[J17]. Wang, H., Ning, F.D., Hu, Y.B., & Cong, W.L., (2018). Surface grinding of CFRP composites using rotary ultrasonic machining: A comparison of workpiece machining orientations. The International Journal of Advanced Manufacturing Technology, 95(5-8), 2917-2930. (IF: 3.4)

[J16]. Wang, H., Cong, W.L., Ning, F.D., & Hu, Y.B., (2018). A study on the effects of machining variables in surface grinding of CFRP composites using rotary ultrasonic machining. The International Journal of Advanced Manufacturing Technology, 95(9-12), 3651-3663. (IF: 3.4)

[J15]. Wang, H., Ning, F.D., Hu, Y.B., Li, Y.C., Wang, X.L., & Cong, W.L., (2018). Edge trimming of carbon fiber reinforced plastic composites using rotary ultrasonic machining: effects of tool orientations. The International Journal of Advanced Manufacturing Technology, 98(5-8), 1641-1653. (IF: 3.4)

[J14]. Wang, X.L., Deng, D.W., Hu, Y.B., Ning, F.D., Wang, H., Cong, W.L., & Zhang, H.C. (2018). Overhang structure and accuracy in laser engineered net shaping of Fe-Cr steel. Optics & Laser Technology, 106, 357-365. (IF: 5.0)

[J13]. Hu, Y.B., & Li, J.Z. (2017). Selective laser alloying of elemental titanium and boron powder: thermal models and experiment verification. Journal of Materials Processing Technology, 249, 426-432. (IF: 6.3)

[J12]. Hu, Y.B., Zhao, B., Ning, F.D., Wang, H., & Cong, W.L. (2017). In-situ ultrafine three-dimensional quasi-continuous network microstructural TiB reinforced titanium matrix composites fabrication using laser engineered net shaping. Materials Letters, 195, 116-119. (IF: 3.0)

[J11]. Hu, Y.B., Ning, F.D., Wang, X.L., Wang, H., Cong, W.L., & Li, Y.Z. (2017). Laser deposition-additive manufacturing of in situ TiB reinforced titanium matrix composites: TiB growth and part performance. The International Journal of Advanced Manufacturing Technology, 93(9-12), 3409-3418. (IF: 3.4)

[J10]. Ning, F.D., Cong, W.L., Hu, Y.B., & Wang, H. (2017). Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties. Journal of Composite Materials, 51(4), 451-462. (IF: 2.9)

[J9]. Ning, F.D., Hu, Y.B., Liu, Z.C., Cong, W.L., Li, Y.Z., & Wang, X.L. (2017). Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: effects of ultrasonic vibration. Procedia Manufacturing, 10, 771-778.

[J8]. Ning, F.D., Wang, H., Hu, Y.B., Cong, W.L., Zhang, M., & Li, Y.Z. (2017). Rotary ultrasonic surface machining of CFRP composites: a comparison with conventional surface grinding. Procedia Manufacturing, 10, 557-567.

[J7]. Ning, F.D., Cong, W.L., Wang, H., Hu, Y.B., Hu, Z.L., & Pei, Z.J. (2017). Surface grinding of CFRP composites with rotary ultrasonic machining: a mechanistic model on cutting force in the feed direction. The International Journal of Advanced Manufacturing Technology, 92(1-4), 1217-1229. (IF: 3.4)

[J6]. Wang, H., Ning, F.D., Hu, Y.B., Du, D.P., & Cong, W.L. (2017). Surface grinding of CFRP composites using rotary ultrasonic machining: design of experiment on cutting force, torque, and surface roughness. International Journal of Manufacturing Research, 12 (4), 461-479.

[J5]. Li, Y.Z., Hu, Y.B., Cong, W.L., Zhi, L., & Guo, Z.N. (2017). Additive manufacturing of alumina using laser engineered net shaping: effects of deposition variables. Ceramics International, 43(10), 7768-7775. (IF: 5.2)

[J4]. Wang, X.L., Deng, D.W., Hu, Y.B., Liu, Z.C., & Zhang, H.C. (2017). Analytical modeling and experimental investigation of laser clad geometry. Optical Engineering, 56(9), 096104. (IF: 1.3)

[J3]. Hu, Y.B., & Li, J.Z. (2016). Ultra-short laser melting of copper nanoparticles: a molecular dynamics study. International Journal of Energy for a Clean Environment, 17(1), 1-25.

[J2]. Wang, H., Ning, F.D., Hu, Y.B., Fernando, P.K.S.C., Pei, Z.J., & Cong, W.L. (2016). Surface grinding of CFRP composites using rotary ultrasonic machining: effects of tool variables. Advances in Mechanical Engineering, 8(9), 1687814016670284.

[J1]. Xu, P., Zhang, C.C., & Hu, Y.B. (2012). Production efficiency optimization with simulated annealing algorithm. Journal of Computer Application, 32(S2), 48-50,60.

Patents

[P1]. Hu, Y.B., & Li, J. Z. (2019) Nano/micro scale porous structured alloys using selective laser alloying process based on elemental powders. U.S. Patent No. 2019/0283135.

Refereed Conference proceedings

[C18] Guo, Z.A., Feng, Y.Q., Hu, Y.B., & Hendrickson, M. Quality improvement in vat photopolymerization of ceramic hollow structures: effects of nanofill thermal buffering method. International Mechanical Engineering Congress and Exposition (IMECE2025-166532), Nov. 16-20, 2025, Memphis, TN, USA.

[C17] Feng, Y.Q., Guo, Z.A., Hu, Y.B., & Hendrickson, M. Process optimization in additive manufacturing of hollow-structured nanocomposites via machine learning. International Mechanical Engineering Congress and Exposition (IMECE2025-165789), Nov. 16-20, 2025, Memphis, TN, USA.

[C16] Liu, C., Jahan, M., & Hu, Y.B. Effects of graphene reinforcements on the mechanical and electrical properties of PDMS printed by inkjet-based additive manufacturing. International Mechanical Engineering Congress and Exposition (IMECE2025-165599), Nov. 16-20, 2025, Memphis, TN, USA.

[C15]. Pandit, P.P., Liu, C., Corti, G., & Hu, Y.B. Fused deposition modeling of carbon fiber reinforced high-density polyethylene: effects on microstructure and mechanical properties. Proceedings of the 2022 Manufacturing Science and Engineering Conference (MSEC2022-85702), June 27-July 1, 2022, West Lafayette, IN, USA.

[C14]. Jahan, M., Hu, Y.B., Yeboah, K., & Stahley, J. Modifying “manufacturing processes” laboratory for online/hybrid learning due to COVID-19. International Mechanical Engineering Congress and Exposition (IMECE2021-70797), Nov. 1-5, 2021, Virtual.

[C13]. Rong, Z.C., Liu, C., & Hu, Y.B. 4D printing of complex ceramic structures via controlling zirconia contents and patterns. Proceedings of the 2021 Manufacturing Science and Engineering Conference (MSEC2021-63642), June 21-25, 2021, Cincinnati, OH, USA.

[C12]. Li, Y.Z., Zhang, D.Z., Wang, H., Hu, Y.B., & Cong, W.L. Laser engineered net shaping of graphene oxide reinforced titanium: effects of reinforcement and laser power. Proceedings of the 2020 Manufacturing Science and Engineering Conference (2021-63642).

[C11]. Hu, Y.B., Wang, H., & Cong, W.L. (2019). Laser deposition-additive manufacturing of graphene oxide reinforced IN718 alloys: effects on surface quality, microstructure, and mechanical properties. Proceedings of the 2019 Manufacturing Science and Engineering Conference (MSEC2019-2985), June 10 – 14, Erie, PA, USA.

[C10]. Hu, Y.B., Wang, H., Li, Y.C., Ning, F.D., & Cong, W.L. (2018). Surface grinding of ZTA parts fabricated by laser engineered net shaping process: effects of ZrO2 content and ultrasonic vibration. Proceedings of the 2018 Manufacturing Science and Engineering Conference (MSEC2018-6663), June 18 – 22, College Station, TX, USA. DOI:10.1115/MSEC2018-6663

[C9]. Hu, Y.B., Maharubin, S., Cong, W.L. & Tan, Z., (2018). Laser engineered net shaping of titanium-silver alloy for orthopedic implant. Proceedings of the 2018 Manufacturing Science and Engineering Conference (MSEC2018-6611), June 18 – 22, College Station, TX, USA. DOI:10.1115/MSEC2018-6611

[C8]. Hu, Y.B., Wang, H., Ning, F.D., Cong, W.L., & Li, Y.Z. (2017). Surface grinding of optical BK7/K9 glass using rotary ultrasonic machining: an experimental study. Proceedings of the ASME 2017 International Manufacturing Science and Engineering Conference (MSEC2017-2780), June 04 – 08, Los Angeles, CA, USA. DOI:10.1115/MSEC2017-2780.

[C7]. Hu, Y.B., Wang, H., Ning, F.D., & Cong, W.L. (2016). Laser engineered net shaping of commercially pure titanium: effects of fabricating variables. Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference (MSEC2016-8812), June 27 – July 01, Blacksburg, VA, USA. DOI:10.1115/MSEC2016-8812.

[C6]. Hu, Y.B., Wang, H., Ning, F.D., & Cong, W.L. (2016) Compressive property comparisons between laser engineered net shaping of in situ TiB-Ti composites and CP-Ti materials. 2016 Annual International Solid Freeform Fabrication Symposium, August 08 – 10, Austin, TX, USA.

[C5]. Wang, H., Hu, Y.B. (2018). Edge trimming of CFRP composites using rotary ultrasonic machining: effects of ultrasonic vibration. Proceedings of the ASME 2018 International Manufacturing Science and Engineering Conference (MSEC2018-6362), June 18 – 22, College Station, TX, USA. doi:10.1115/MSEC2018-6362

[C4]. Wang, H., Hu, Y.B., Ning, F.D., Li, Y.Z., Zhang, M., Cong, W.L., & Smallwood, S. (2017). Surface grinding of CFRP composites using rotary ultrasonic machining: effects of ultrasonic power. Proceedings of the ASME 2017 International Manufacturing Science and Engineering Conference (MSEC2017-2726), June 04 – 08, Los Angeles, CA, USA. DOI:10.1115/MSEC2017-2726.

[C3]. Ning, F.D., Hu, Y.B., Liu, Z.C., & Cong, W.L. (2016). Microstructural and mechanical performance of Al2O3 nanoparticle reinforced 17-4 PH stainless steel bulk composite parts fabricated by laser engineered net shaping process. 2016 Annual International Solid Freeform Fabrication Symposium, August 08 - 10, Austin, TX, USA.

[C2]. Zhang, D.Z., Wang, H., Hu, Y.B., Chen, X.X., Cong, W.L., & Burks, R.A. Rotary ultrasonic machining of CFRP composites: effects of carbon fiber reinforcement structure. Proceedings of the 2019 Manufacturing Science and Engineering Conference (MSEC2019-3014).

[C1]. Chen, X.X., Wang, H., Hu, Y.B., Zhang, D.Z., Cong, W.L., & Burks, R.A. Rotary ultrasonic machining of CFRP composites: effects of machining variables on workpiece delamination. Proceedings of the 2019 Manufacturing Science and Engineering Conference (MSEC2019-3019).

Posters

[P9]. Hu, Y.B., Wang, H., Li, Y.C., Ning, F.D., Cong, W.L., & Beskow, K. (2018). Surface grinding of ZTA parts fabricated by laser engineered net shaping process: effects of ZrO2 content and ultrasonic vibration. Proceedings of the ASME 2018 International Manufacturing Science and Engineering Conference (MSEC2018-6741), June 18-22, 2018, College Station, TX, USA.

[P8]. Hu, Y.B., Wang, H., Ning, F.D., Cong, W.L., & Ericson, H. (2017). Surface grinding of optical BK7/K9 glass using rotary ultrasonic machining: an experimental study. Proceedings of the ASME 2017 International Manufacturing Science and Engineering Conference (MSEC2017-3110), June 4-8, 2017, Los Angeles, CA, USA.

[P7]. Hu, Y.B., Wang, H., Ning, F.D., & Cong, W.L. (2016). Laser engineered net shaping of commercially pure titanium: effects of fabricating variables. Proceedings of the ASME 2016 International Manufacturing Science and Engineering Conference (MSEC2016-8895), June 27-July 01, 2016, Blacksburg, VA, USA.

[P6]. Hu, Y.B., Ning, F.D., Wang, H., & Cong, W.L. (2016). Laser engineered net shaping of in situ TiB-Ti metal matrix bulk composites: microstructure evolution and mechanical behavior. 2016 Annual International Solid Freeform Fabrication Symposium, August 8-10, Austin, TX, USA.

[P5]. Wang, H., Hu, Y.B., Cong, W.L., & Burks, A. (2019). A mechanistic model on feeding-directional cutting force in surface grinding of CFRP composites using rotary ultrasonic machining with horizontal ultrasonic vibration. Accepted at the Proceedings of the ASME 2019 International Manufacturing Science and Engineering Conference (MSEC2019-3136), June 10-14, 2019, Erie, PA, USA.

[P4]. Wang, H., Hu, Y.B. (2018). Edge trimming of CFRP composites using rotary ultrasonic machining: effects of ultrasonic vibration. Proceedings of the ASME 2018 International Manufacturing Science and Engineering Conference (MSEC2018-6732), June 18-22, 2018, College Station, TX, USA.

[P3]. Wang, H., Hu, Y.B., Ning, F.D., Cong, W.L., Smallwood, S. (2017). Surface grinding of CFRP composites using rotary ultrasonic machining: effects of ultrasonic power. Proceedings of the ASME 2017 International Manufacturing Science and Engineering Conference (MSEC2017-3111), June 4-8, 2017, Los Angeles, CA, USA.

[P2]. Ning, F.D., Wang, H., Hu, Y.B., & Cong, W.L. (2016). A parametric study of tensile properties of CFRP composite parts fabricated by fused deposition modeling. 2016 Annual International Solid Freeform Fabrication Symposium, August 8-10, Austin, TX, USA.

[P1]. Zhang, D.Z., Chen, X.X., Wang, H., Hu, Y.B., Cong, W.L., & Burks, R.A. Rotary ultrasonic machining of CFRP composites: effects of carbon fiber reinforcement structure and machining variables. Accepted at the Proceedings of the 2019 Manufacturing Science and Engineering Conference (MSEC2019-3137), June 10-14, 2019, Erie, PA, USA.

Presentations

Invited talk

- State-of-the-Art in Additive Manufacturing. To fifth graders of Talawanda School during the Science Day event, May 2023

- Facilities, equipment, and other resources in MME department at Miami University. To high school students during the Make it Miami event held at Miami University, April 2023

- Acoustic field-assisted additive manufacturing, United Performance Metals visit, Apr. 2023.

- Acoustic field-assisted additive manufacturing of various materials, Vebleo Webinar, Jan. 2022.

- Additive manufacturing of high-performance materials, Guest lecture to West Virginia University, Oct. 2021.

- Additive manufacturing: significance of design, simulation, and teamwork. A guest lecture for the summer scholars program at Miami University, Jul. 2021.

- Field-assisted 3D printing and 4D printing of ceramics. CEC faculty research seminar at Miami University, Nov., 2020.

- Directed energy deposition of ceramic and ceramic reinforced composites, ECE/MME talk, Miami University, Sep. 2019.

Proceedings of the Manufacturing Science and Engineering Conference

- Laser deposition-additive manufacturing of graphene oxide reinforced IN718 alloys – Erie, PA, USA, 2019

- Surface grinding of ZTA parts fabricated by laser engineered net shaping process: effects of ZrO2 content and ultrasonic vibration – College Station, TX, USA, 2018

- Laser engineered net shaping of titanium-silver alloy for orthopedic implant – College Station, TX, USA, 2018

- Surface grinding of optical BK7/K9 glass using rotary ultrasonic machining: an experimental study – Los Angeles, CA, USA, 2017

- Laser engineered net shaping of commercially pure titanium: effects of fabricating variables – Blacksburg, VA, USA, 2016

Annual International Solid Freeform Fabrication Symposium

- Alumina-zirconia ceramics fabricated by ultrasonic vibration-assisted laser engineered net shaping process – Austin, TX, USA, 2017

- Laser engineered net shaping of in situ TiB-Ti metal matrix bulk composites: microstructure evolution and mechanical behavior – Austin, TX, USA, 2016

Contact

- McCain Engineering, Starkville, MS, USA

- 260F McCain Hall